Welcome to Project Landshark.

Witness what happens when two decades of passion for Fox-Body Mustangs collides with focused research in an effort to create the ultimate "Do it all" Fox.

Where do we start? We start where we always do, with a person who had a vision. Meet Chris; the proud owner and mad scientist of our aptly named 'Project Landshark.' Chris has been building and racing a number of Fox Bodies since his first in 1992. With each successive build, Chris pushed boundaries, trying new parts from various aftermarket companies, always progressing forward towards the goal of the ultimate Fox Body. But, what is the ultimate Fox? Well dear reader, this is always a subjective answer, deeply personal to each owner. Everyone searches for the "do it all" car and everyone's answers differ slightly. For some, it's a 1,200 horsepower monster capable of running a low 8 and then taking the misses out for ice cream afterwards. For others, its the ability to devour a road course lap after lap and drive home in air conditioning. For Chris, the formula is a bit wider. Chris is on the hunt for a vehicle which can knock off an impressive quarter mile time, run the Texas Mile similarly to most modern super cars, make short work of a road course, dodge cones with the best of them, and still be comfortably driven to Church on Sunday.

Enter project Land Shark, a vehicle designed to be an apex predator on pavement, built from generations of evolution into the perfect killing machine.

Like every great build, the planning phase is everything. Chris went to the drawing board, looking at years of past experience and research on suspension systems, aero setups, power plants, and performance components. He searched far and wide, discussing setups with Griggs, Maximum Motorsports, and Ride Tech, but felt he was missing that secret sauce he knew would be required to execute his plan. The light bulb went off the moment he contacted Vinny Algretta of VA Motorsports. Vinny was the bridge to taking Chris's idea and turning it into a real plan. Vinny was quick to point out that to make something that few have attempted, you need to swim in the deep waters where anything is possible. The two knew immediately that there was only one place to go for the chassis and suspension, CorteX Racing.

And so, our involvement with this amazing project began. CorteX, along with Chris, Vinny, and graphic designer Shivam Carboy turned dreams into a render, and laid a plan to turn the render into reality. And my, what a render we have. Landshark will feature a complete vehicle overhaul.

Underneath, the car will of course feature our entire CorteX catalog. From a front SLA to a cambered fabricated rear 9" axle, complete with torque arm and watts link this car is going the get the whole works.

Initially, this 1989 Notch started life as a drag car before being acquired by Chris and promptly sent over to VA motorsports. The vehicle was a bit of a rolling project car. A perfect foundation for a bigger build but, definitely still needed some love. Once at VA, Vinny and the team began the painstaking task of stripping the vehicle down removing the interior, cleaning up the sheet metal, wiring & sound deadening, and turning the car into a high-quality chassis ready for reconstruction.

With a great deal of the grunt work done, the car was transported from VA Motorsports over to our shop in Cincinnati Ohio for the metal work to begin.

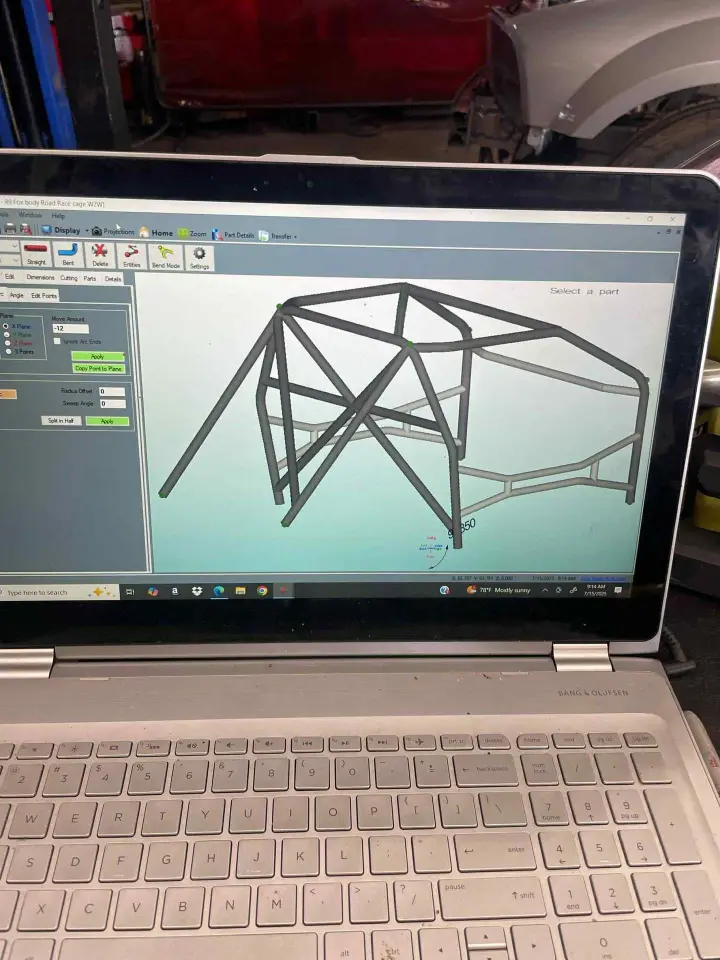

With a discussed plan, and some CAD work quickly done, the guys set about further disassembling the car.

First on the list was removing necessary interior pieces which would allow us to mount the cage. A custom dash is going to be put in this vehicle so we will integrate some mounting points directly to the behind-the-dash cage cross bar.

Next, everyone knows a great performance car takes maximum advantage of wheel well space. In this case, we are going to cram the largest tire we can possibly fit (likely in excess of 325mm) under this mildly flared car. That means we will need some more inboard clearance, necessitating the use of a mini-tub kit.

With the wheel wells cut out, the guys got to work adding the mini-tub and tacking it into place.

In addition to the tub, LandShark is going to get a full racing style fuel cell. The rear trunk floor would need to be sacrificed to make the Fuel-Safe unit fit, so out it came.

Before we decided to move onto the cage work, the team installed a custom close-out panel, separating the fuel cell area from the passenger compartment.

We also added another custom close-out to clean up the rear package tray area at the base of the back windshield.

Next up, time for some cage work. We started by sighting the main hoop.

Then started working on the myriad of down-bars. The close-out panels were removed temporarily to allow for accurate bar placement.

With the rear of the cage largely in place, the team then turned their attention to the front half of the cage and the door bars.

And a quick fitment check with the customer provided carbon bucket seats...

Cage largely completed, it was time to turn our attention to suspension hard points. We have been seeing more and more fabricated 9" axles being requested on these resto-mod builds. We are constantly asked about the "best way to go" from an axle standpoint. For builds under 1,000 horsepower and where constant gear changes are not required, ultimately prefer the 8.8" units due to their smaller size and weight. For builds with big power, and/or the need to make frequent gear changes, the 9" is the way to go. Factory cast housings are totally adequate, but these fabricated 9's are a work of art and look like serious business.

This 9" axle has been converted to one of our cambered units, giving project landshark about 2 degrees of negative rear camber thanks to the ball bearing drive system and end units. You can read more about our cambered axles here.

As part of our axle construction services, we will custom cut the unit, add on all necessary control arm bracketry, and verify that the total lengths are set up to be perfectly mated to your wheels for optimal fitment. You can see our custom axles here.

Also pictured above, and included in our rear suspension systems, is our watts link. In this instance, a custom cross brace was welded in, as was the central pivot support bracket directly to the 9" axle. The fabricated housings make adding the watts link a relatively painless affair since the housing is nice and flat.

While simply using set-up rods to simulate ride-height, LandShark is going to get a very nice set of custom valved MCS coil-overs front and rear.

In our next episode, we are going to cover the front SLA, the shocks, and custom tubular front end..